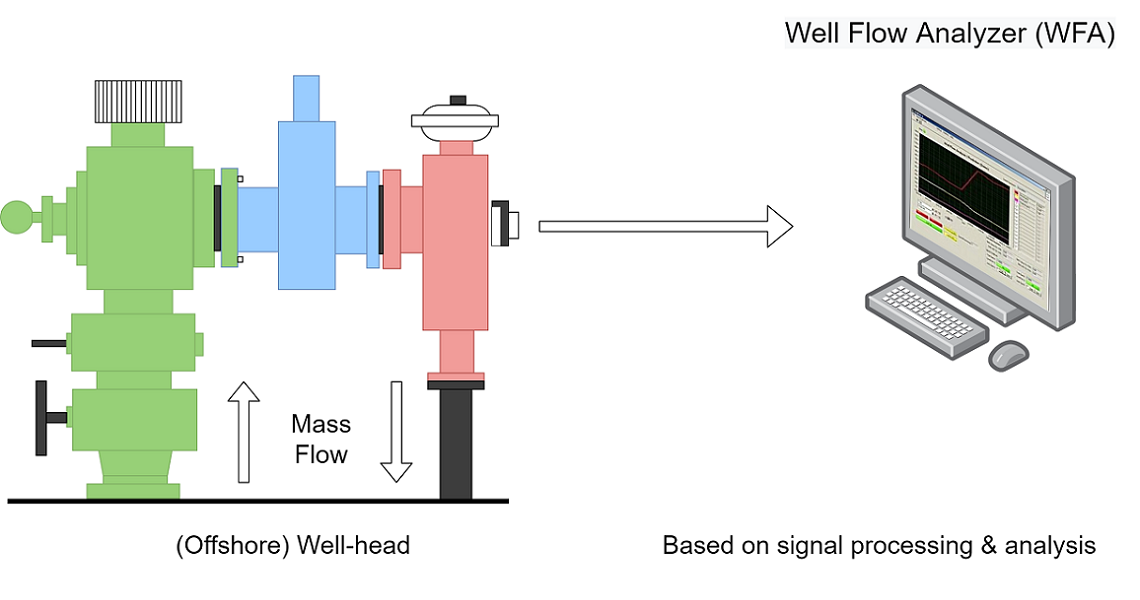

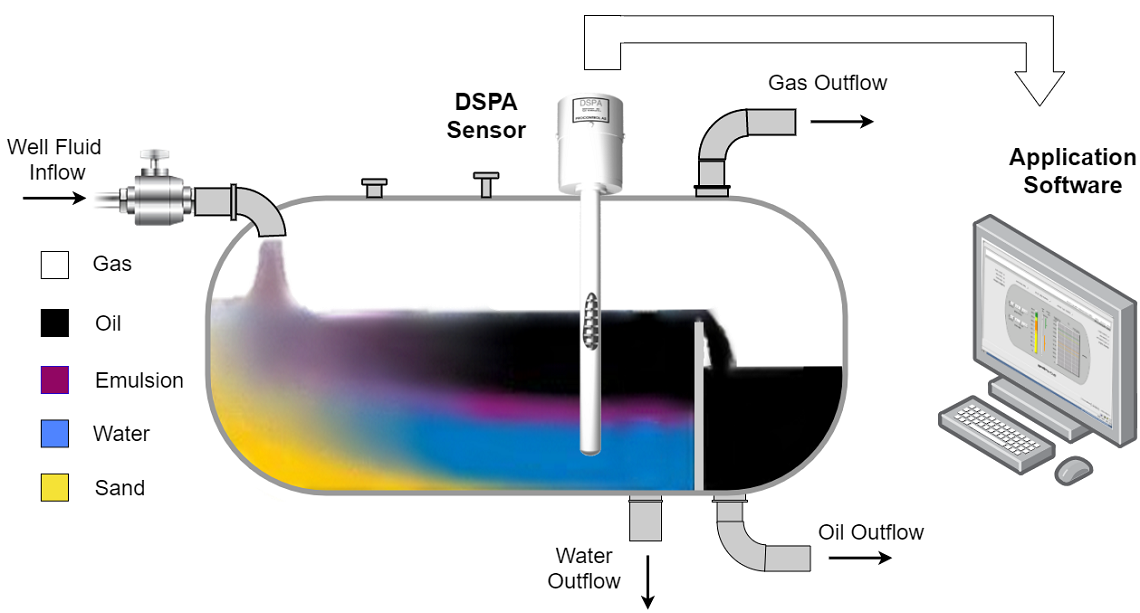

The Well Flow Analyser is invented by Sensorteknikk. The principle could be described as a principle extracting information in acoustic signals from a multiphase fluid that passes through a choke valve or turbulence creating means. The principle is based on the fact that a fraction of the kinetic energy of the through flowing fluid is transformed into acoustic energy, which contains a broad acoustic spectrum. This spectrum is a function of several parameters that characterize the composition of the flow. The acoustic signals are picked up by an acoustic sensor clamped on the outside of a choke valve or another suitable flow conditioning means.

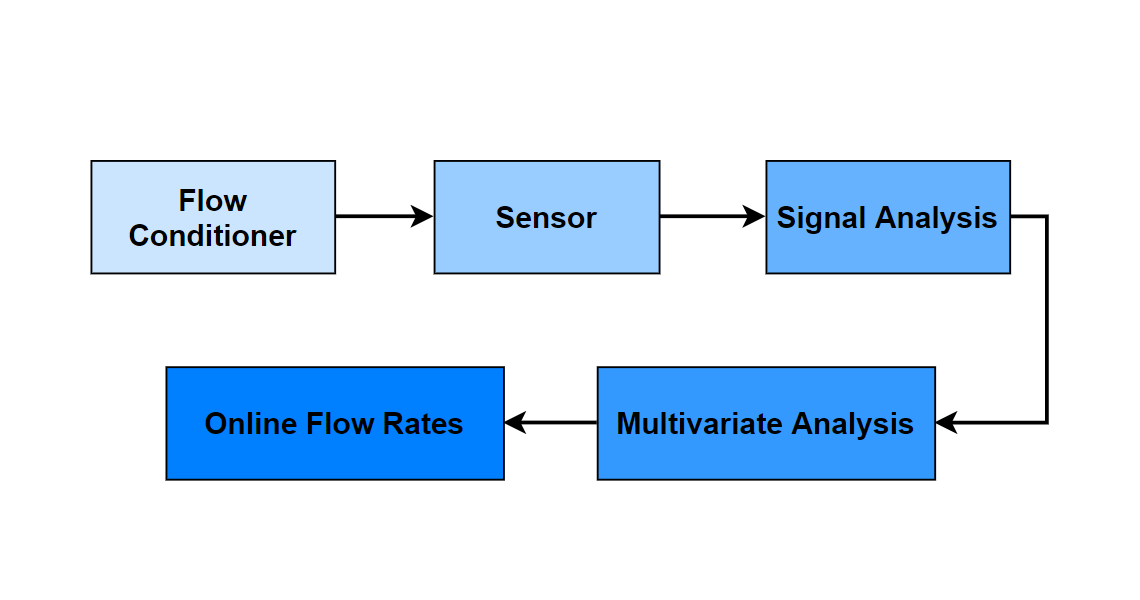

By processing the acoustic signals and then use multivariate data analysis, models are built based on existing data and could be used for future prediction of incoming data. The compositions and amount of oil, gas, water and particle content in the flow are then obtainable for the user.

The sensor installation is straightforward and does not require modification of flow lines or valves. Test installations made by Sensorteknikk at various test rigs and facilities, i.e., Trecate Italy, Ceesi Colorado and Kårstø Norway, successfully verify that the WFA is one of the most accurate ways to perform a multiphase flow metering.